Email: business@hiwin.cn

No. 2, Xiazhuang Road, Industrial Park, Suzhou, Jiangsu, China

TEL: +86-512-80685599

HOTLINE

+86-512-80685599

The Silver Delta robot maintains high efficiency with a vision system that can complete 120 fly-catching packages per minute.

The founder of HIWIN, the president of Zhuo Yongcai, proposed to create a new thinking: "Manufacturing is not an end, it is to meet human needs, manufacturing is a service, and service is the source of innovation." Shangyin Technology is a ball screw drive positioning function. Starting from the diversification of parts, subsystems, systems, machine and medical products, what kind of service and added value can the industry provide for the next generation of products? After years of accumulated research and development energy, the company's R&D products have been updated, and the strength of intelligent manufacturing and intelligent services has been greatly recognized.

HIWIN sincerely invites you to visit the Shanghai New International Expo Center (1500 Hall E1) on March 20-22, 2019 to visit the 2019 Munich Shanghai Electronics Manufacturing Equipment Exhibition, giving you a chance to guide many new products.

HIWIN will work with you to move towards Industrial 4.0 Smart Manufacturing.

Welcome to the HIWIN Shanghang booth (1500 Hall E1)!

2019 Munich Shanghai Electronic Production Equipment Exhibition

Time: 2019/3/20-22

Venue: Shanghai New International Expo Center

Booth: 1500 Hall E1

1. Parallel robotic arm (Delta Robot)

The Silver Delta robot maintains high efficiency with a vision system that can complete 120 fly-catching packages per minute

The visibility of machine vision in production online is getting higher and higher. Instead of manpower, it can often reach the speed and precision that the human eye can't reach. With the integration of automation system, machine vision plays an important role in the production line to increase production capacity.

In the packaging production line, the food industry is unable to rely solely on manual operations because of the large number of products. In the future, it is a necessary process to introduce robots online to solve the labor shortage.

HIWIN's biscuit packaging line, in addition to the rapid movement of the Delta robot, with a sophisticated visual identification system, so even if the feed is disorderly placed, Delta can use the suction cup to the conveyor belt correctly, reducing Manually sorted pre-process. Together with the infrared sensor at the source of the conveyor belt, Delta achieved 99.5% of the correct grip rate.

The Shangda Delta robot has an IP 65 degree of protection, enabling industrial users to implement automated production line applications to comply with safety and hygiene standards; according to EN1672-2, the food industry can also use robotic arms to achieve automated production and avoid production lines. Pollution can meet the guidelines for good food hygiene standards.

2. i4.0BS Smart Lead Screw - Winner of the 2018 International Innovation Award

The first intelligent ball screw with Industry 4.0 connection, its sensing design can effectively monitor the performance of ball screw; the operator can know the ball screw preloading state, screw temperature rise and displacement, screw vibration by intelligent module. Quantity, optimal lubrication time, in order to maintain the quality and efficiency of the process, the manager can remotely grasp the status of each machine in real time by APP, and avoid the generation of defective products in advance to plan the production schedule and maintenance plan.

3. Torque Motor Rotary Workbench

The Torque Motor rotary table produced by HIWIN has performance beyond mechanical transmissions such as worm gears and roller cams. It has a higher speed and is equipped with a water-cooled torque motor. In addition to reducing thermal deformation, it can increase working torque and achieve high dynamic response and accuracy. Together with zero backlash and zero wear, it can improve Torque. The reliability of the Motor rotary table increases added value.

In addition to water-cooled torque motors, the Torque Motor rotary table is also equipped with high-precision bearings, absolute encoders and powerful brakes to achieve a high-performance rotary table.

Widely used in a variety of industries: automotive industry parts processing, semiconductor precision parts processing, mold processing, aerospace and medical equipment, high-precision machining of complex parts.

● Two-axis rotary table (RAB/RAS series), a key component of the high-end five-axis machining machine.

● Single-axis rotary table (RCV/RCH series), used in the milling and machining center, with a speed of 2,000 RPM.

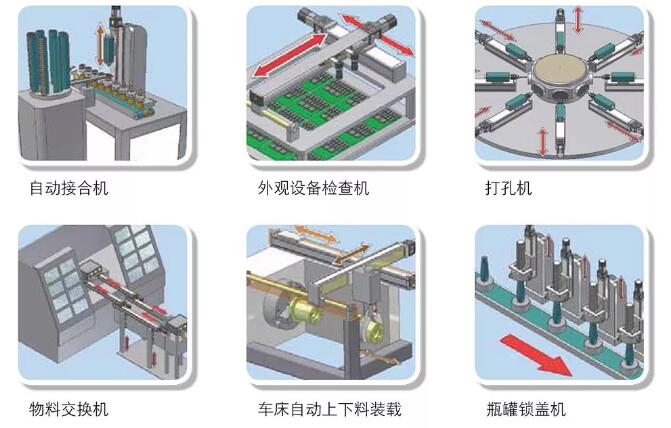

4. Total Solution for Single-Axis Robots, Motors and Drives

● HIWIN single-axis robots are mainly designed to integrate ball screws and linear guides with servo motors and drives through a modular design. High-precision ball screw is used as the transmission mechanism to achieve high precision, high efficiency, small size and fast installation.

● Provide integrated solutions for customer organizations and electronic control, combined with single-axis robots, servo motors and drives, significantly reducing customer assembly time and installation space.

● Suitable for high precision industry, semiconductor industry, medical automation industry, FPD panel handling, testing or test environment.

HIWIN Choice Program

Product Application Examples

5. Articulated Robot

● The lightweight and articulated robotic arm, with its many degrees of freedom and high flexibility, can be used for handling of products or for complex machining tasks.

● It is suitable for object picking and stacking, workpiece deburring and grinding, and component assembly.

6. SCARA Robot

The Scala robot arm is suitable for quick access to or assembly of objects in a flat range, and is widely used in the plastics industry, the automotive industry, the electronics industry, the pharmaceutical industry, and the food industry.

7. Wafer Robot

The components can be 100% self-made and the software is developed by itself. It has vertical integration of software and hardware and is highly competitive. High precision, high rigidity direct drive motor with repeatability of ± 0.02mm. High space usage and small radius of gyration. Applicable to the semiconductor industry (wafer pick and place), optoelectronic industry (small panel and small solar panels), LED industry (sapphire substrate, rubber ring) and other pick and place equipment.

One-armed

Bijrus

8. SSA single-axis linear motor platform

Features:

●The shortest delivery date is 1 week

●Maximum speed 5000mm/s

●High resolution 0.1µm

●Optimal reproduction accuracy ±1µm

●With HIWIN drive D1

Application Industry:

● Suitable for electronic automation industry