Email: business@hiwin.cn

No. 2, Xiazhuang Road, Industrial Park, Suzhou, Jiangsu, China

TEL: +86-512-80685599

HOTLINE

+86-512-80685599

Screw Doctor

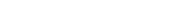

Destruction mode:Erosion

Denudation is a form of contact fatigue failure of materials. When the steel ball rolls, the initial crack occurs in the maximum shear stress region of the subsurface of the track, and the crack grows to the surface of the material after the reverse stress, and the morphology of the hole is formed after the material is peeled off.

The main cause:

The theoretical life is used and the contact position is too high.

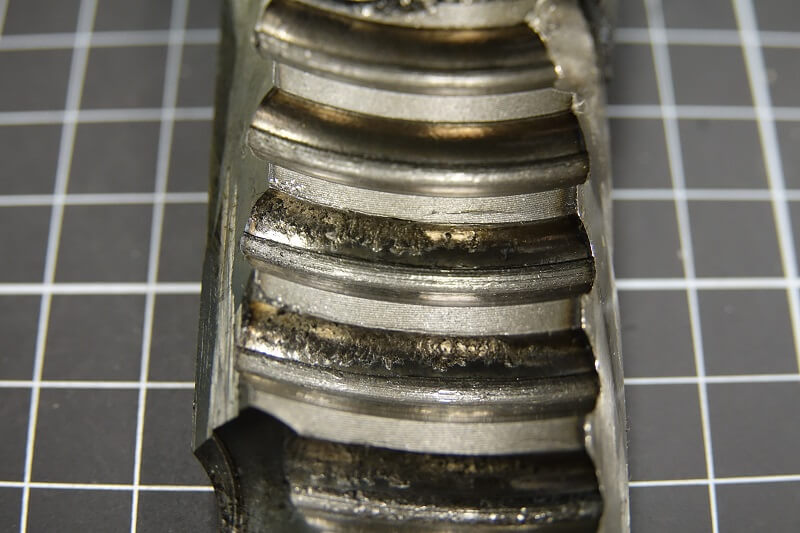

Destruction mode:Corrosion

A water-containing liquid or an environment with high temperature difference and high humidity causes moisture to cause rust on the screw, and even causes large-scale rust even after long-term operation.

The main cause:

High humidity environment, aqueous solution intrusion, grease grease protection failure.

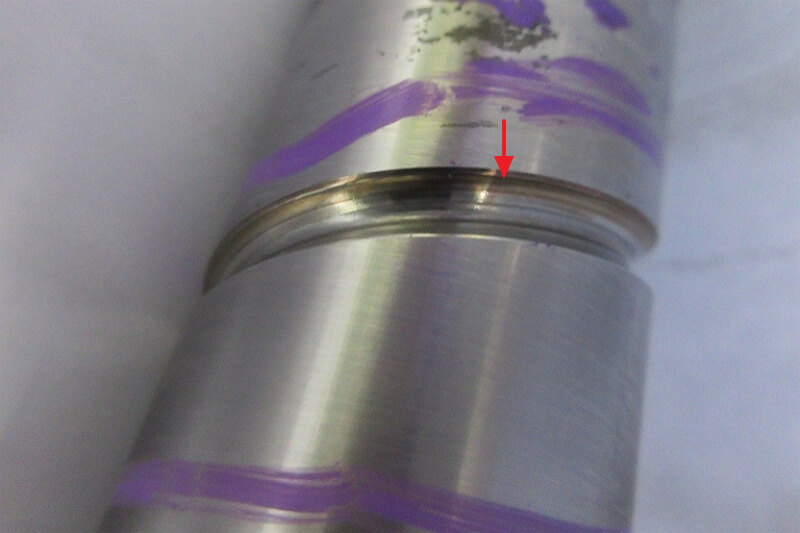

Destruction mode:Burn

When the screw is subjected to a load, frictional force is inevitably generated. In the case of insufficient lubrication, the frictional heat cannot be effectively removed, and the lubricant cannot function normally, resulting in overheating of the raceway surface.

The main cause:

Poor lubrication and heavy load.

Destruction mode:Rupture

Excessive load causes the steel ball to flow back unsmoothly, causing stress concentration and abnormal wear on the track surface, which exceeds the material's tolerable range and eventually causes the surface to crack.

The main cause:

The external impact force is too large and the cycle is abnormal.

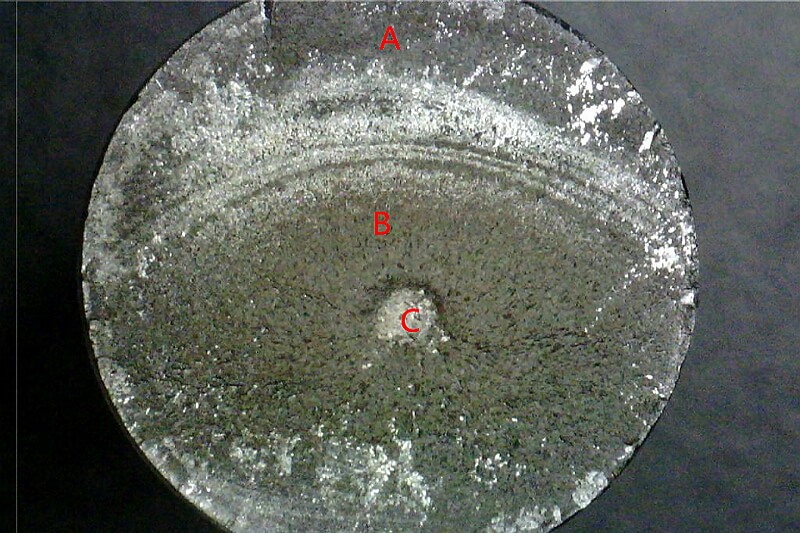

Destruction mode:Shoulder break

During operation, the shoulder of the screw is repeatedly subjected to bending force, so that the initial crack is finally broken from A→B→C.

The main cause:

The assembly yaw is too large, the shoulder geometry is too large, and the shoulder strength is insufficient.

Destruction mode:Foreign body invasion

In high dust environments, external dust can not be effectively isolated from the inside of the invading nut. Prolonged use will result in unsatisfactory operation and even blockage of the return system.

The main cause:

The particle size of the powder is less than the protection of the dustproof fitting.

Destruction mode:Cutting fluid, coolant intrusion

The cutting fluid, the coolant and the lubricating grease collide, resulting in abnormal failure and discoloration of the grease.

The main cause:

Pipeline leakage, protection failure, deterioration of lubricating grease.