Email: business@hiwin.cn

No. 2, Xiazhuang Road, Industrial Park, Suzhou, Jiangsu, China

TEL: +86-512-80685599

HOTLINE

+86-512-80685599

Ballscrew Doctor

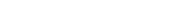

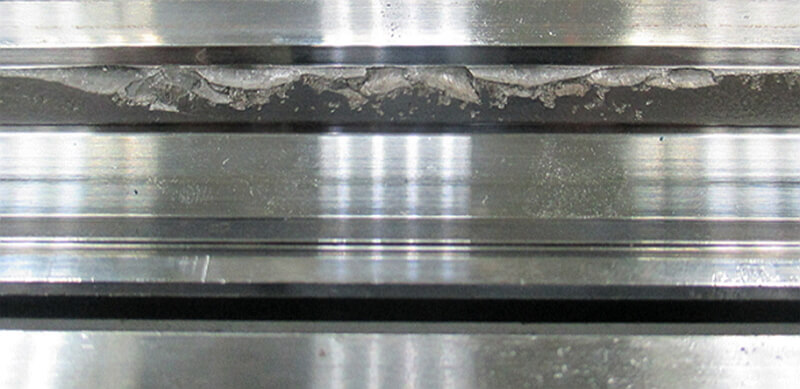

Destruction mode:Flaking

Corrosion damage is a kind of fatigue damage of materials. Under normal circumstances, due to the influence of maximum shear stress, cracks are generated under the surface of metal. Because of the continuous action of maximum shear stress, cracks under the surface will extend to the surface, resulting in Denudation occurs.

Main cause:

The life is not selected, the load is too heavy, the lubrication is poor, and the foreign body invades.

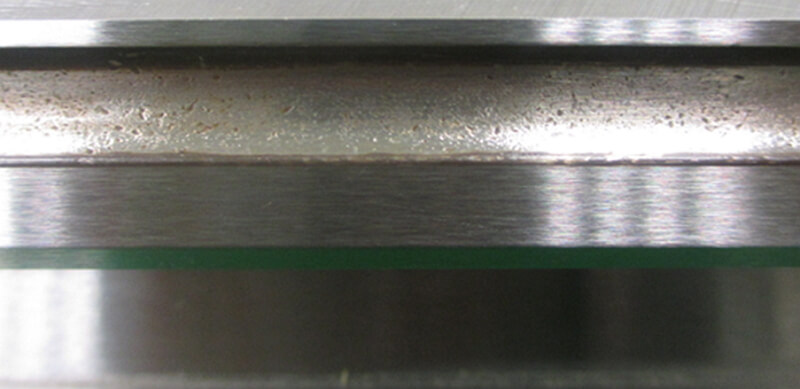

Destruction mode:Corrosion

After the oil film is worn away, the water, acid and alkali solution will directly adhere to the exposed metal part, and the lubricity will decrease, which will lead to corrosion of the track, and rust will become the cause of early erosion.

Main cause:

Poor storage, insoluble water-soluble coolant, high humidity environment.

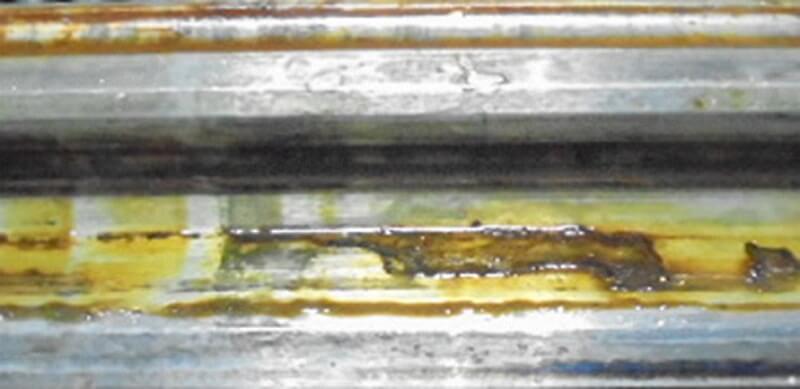

Destruction mode:Aqueous solution invasion

Infiltration of water-soluble coolant, lubrication and rust prevention will decrease, resulting in corrosion of linear slides. This causes erosion.

Main cause:

High humidity environment, aqueous solution invasion.

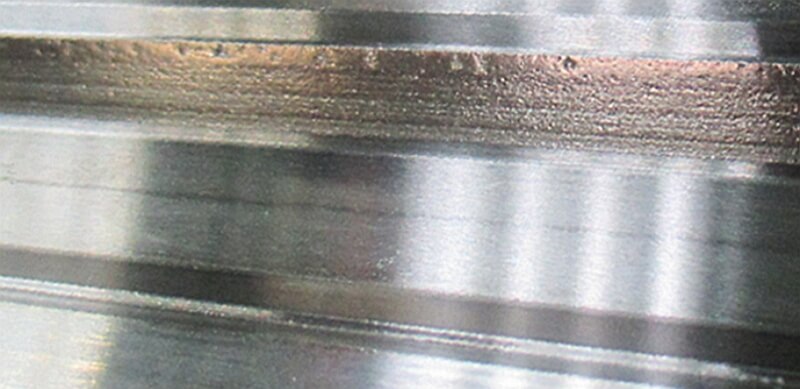

Destruction mode:Burn

Because of the heat generated by friction, discoloration, low hardness, and poor lubrication of the rotating body occur, resulting in most relatively small melting traces in the track, which makes the rolling surface uneven and eventually leads to erosion damage.

The main cause:

Poor lubrication, heavy load

Destruction mode:Rupture

Excessive load can cause poor rolling cycle of the rolling elements, resulting in abnormal wear and stress concentration in the track.

The main cause:

The external impact force is too large and the rolling element circulation is poor.

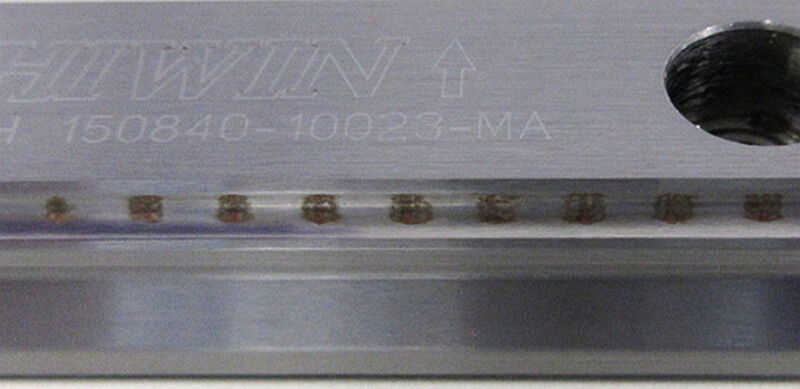

Destruction mode:Indentation

When the oil film disappears at the contact point of the rolling element under the micro-motion motion, the relative sliding friction between the metal and the metal causes the fine powder to be generated, the fine powder is continuously rubbed, the accelerated wear and the fine powder will produce the ball-interval indentation, and the indentation state will be affected. The roughness of the rolling surface and the influence of the oil film thickness.

The main cause:

Micro-twisting, poor lubrication, and excessive load.